Papier Sprick at LogiMAT 2025: Versatile system solutions for your packaging process

We look back on three exciting days at LogiMAT in Stuttgart. From 11-13 March, 1,500 exhibitors presented the latest innovations in intralogistics and process management to around 65,700 visitors on the theme of ‘Passion for Solutions’. This year, we once again took the opportunity to present our comprehensive range of sustainable transport protection solutions that optimise shipping processes.

The focus of our trade fair presentation this year was on the versatility of our innovative system solutions and our ongoing commitment to developing eco-friendly, customised packaging processes.

Our trade fair highlights

Sustainable alternative PaperJet® winder

We exhibited the PaperJet® Winder as a sustainable alternative to industrial cushioning solutions made of foam and plastic. The system demonstrates its advantages particularly in an industrial context for heavy and sensitive goods. The flexible production of the paper cushioning coils enables product-specific and reliable transport protection: pre-production, just-in-time and different densities can be selected as required. Thanks to its simple operation, the PaperJet® Winder offers a clear advantage over PU foam solutions that require training. The eco-friendly paper cushioning coils are made from 100% recycled paper and therefore support a sustainable packaging process.

Would you like to see the PaperJet® Winder in action? We would be happy to present our solutions to you in a personal, free and non-binding live presentation and answer all your questions.

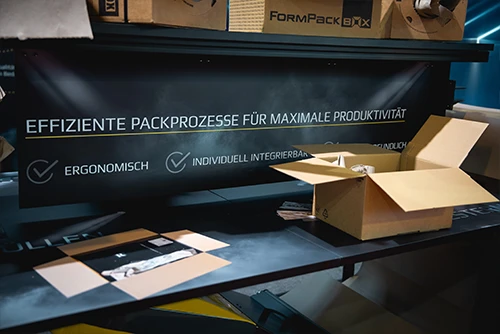

Versatile void fill and cushioning solutions for your packing table

With a combined packing table integration, we showed how versatile our void fill and cushioning solutions can be integrated into the customer’s packing situation. Both our proven standard frames for our compact systems and a PaperJet® under-table solution were used here. The benefits for our customers: ergonomic workstations, optimised processes and consumables made from recycled paper to strengthen the perception of sustainability.

Do you still have questions about our void filland cushioning solutions? Then book a personal, free and non-binding live presentation and we will help you with any uncertainties.

Customised shipping packaging and automated processes

This year, we accompanied the presentation of the VariMailer® Pro with a video display that emphasised the particularly simple operation of the system and the advantages of V-Mail®. The system is the fully automated solution for the production of dispatch packaging. It primarily supports senders with a high shipping volume and enables them to automate the process, increase efficiency and work cost-effectively. Furthermore, the rental system allows users to benefit from flexible packing station organisation.

We would be happy to give you a personal, free and non-binding live presentation to show you how the VariMailer® Pro can optimise your shipping process.

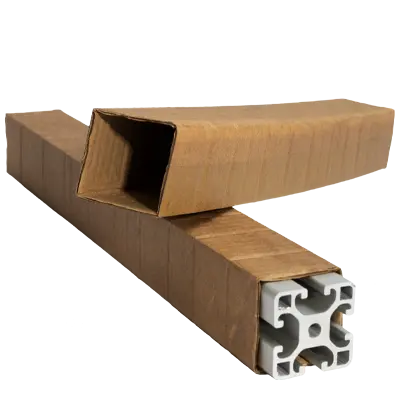

Eco-friendly transport protection made from recycled paper

The topic of sustainability was also addressed on the opposite side of our stand: here we displayed a packing table with samples from our range of transport protection profiles. Tube packaging, edge protection and packaging paper could be tested directly on the product, showing visitors to the stand sustainable alternatives to plastic packaging.